We are thrilled to be introducing new and exciting fabrics into the Next State range. In addition to our natural fabrics we will now be printing onto Polyester. With the investment of a new printing machine especially designed for polyester printing and in-depth trials of different base cloths we are introducing the first four fabrics available for printing

Hampton

The Hampton fabric has been woven to replicate the textural characteristics of linen. With a slightly open weave Hampton provides a luxurious look for an interior textile. The textile is suitable for domestic and commercial applications. Hampton has been tested and graded use as a commercials textile.

Aspen

Aspen has a beautiful surface sheen and soft hand feel making it an opulent textile. Aspen has been woven with fine polyester yarn into a structure creating a diamond appearance. This weave structure adds dimension to the textile and makes it feel like a velvet. Aspen is suitable for both domestic and commercial applications.

Crepe

Crepe de chine is a soft drapey and slightly textured weave. The Next State crepe is a light-weight crepe making it perfect for fashion garments. Crepe is an incredibly popular fabric to wear as it hangs effortlessly off the body is extremely flattering and has beautiful print reproduction.

Satin

Polyester Satin is a flowing and light weight fabric, it has a luxury sheen across the surface and a matte finish on the inside of the fabric. It is tightly woven and has a very soft and fluid hand feel. Polyester Satin looks both lovely and is also a very durable fabric.

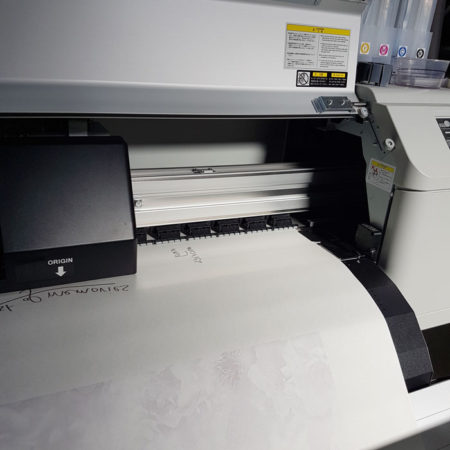

The Process

Polyester is digitally printed using a process called dye-sublimation. A textile dye (disperse is used for polyester) is printed onto a paper. The paper is especially made for digital printing. The image is printed onto the paper in the reverse. Once the paper is printed it is placed onto the surface of the textile. Using a large heater the paper and fabric pass through the heater under pressure and the image transfers from the paper onto the fabric. This transfer of the dye is the sublimation process, a solid being the dye, becomes a gas and the colour molecules explode into the fabric and permanently dye the fibres. Then we have our artwork on the fabric!

The artwork is first printed on to paper using our wide format digital printer.

The fabric and paper are aligned and passed through the heater.

The printed paper is soft in colour when the dye is added to the surface. Once the polyester fabric has been sublimated the full and true colour of the artwork is bought to life.